Recognize, identify, control

We support you in the automatic identification of your objects, whether individually, in containers or on pallets. Our solutions include various Auto ID systems such as RFID, localization and voice recognition for production, logistics and supply chain.

Our customers value us as a competent, innovative partner who is committed to supporting them from the initial problem analysis to the final goal.

Examples for applications and solutions

In production, we can identify components using RFID transponders before assembly and then document individual assembly steps. By means of internal tracking, we optimise your production processes. Continuous order tracking also ensures greater stock reliability.

By means of indoor localisation, your items can be recognised and identified within a block storage or high-bay warehouse within a plant. By means of an RTLS system, real-time localisation can also be carried out via localisation. Many years of project experience of our employees form the foundation for effective Auto ID and RFID solutions for production, supply chain, warehouse and logistics:

Invest now & pay later

Invest in your future despite a weak order situation. Optimize your processes with our software & hardware and increase your production. Our financial partner takes over the planning and implementation costs for up to 9 months and considers funds from subsidy programs. This way you finance your projects only after implementation and start of going live.

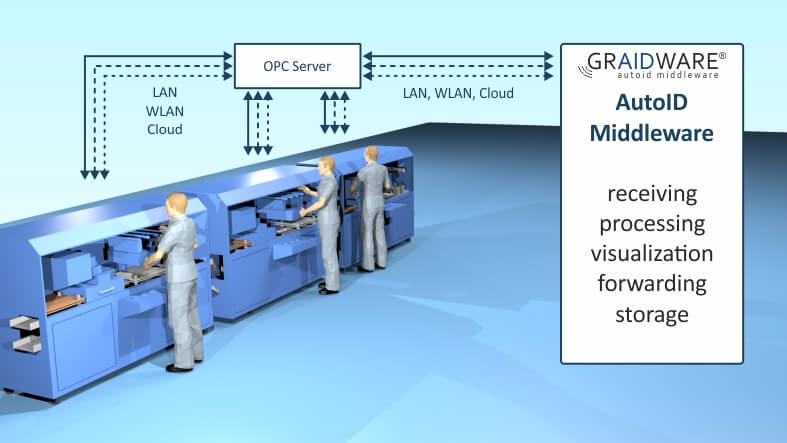

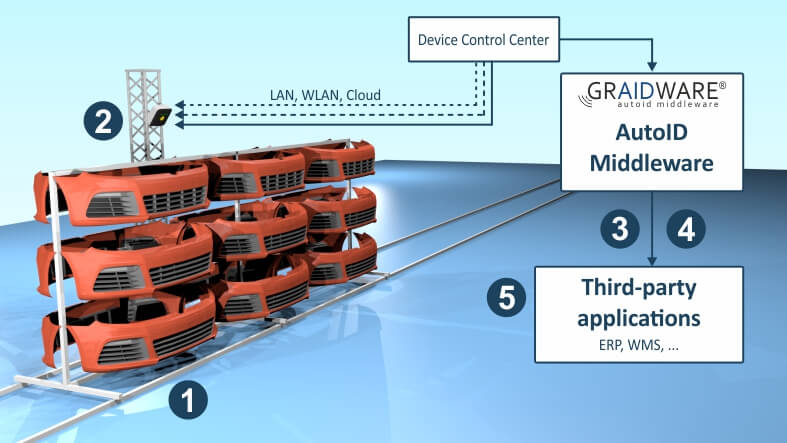

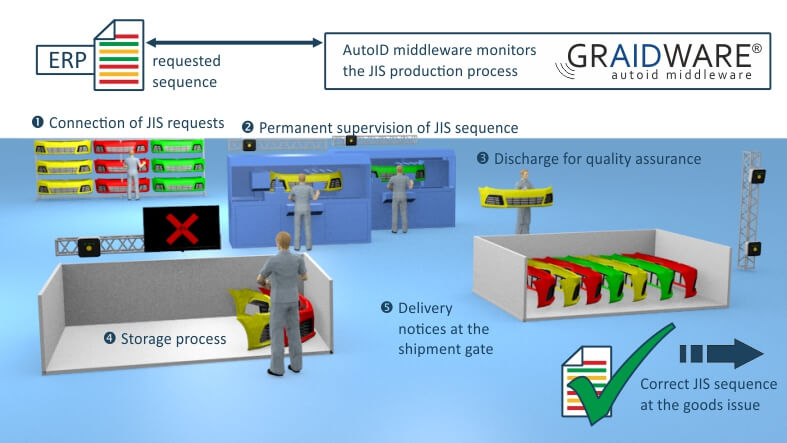

UHF RFID technology enables automated production and logistics control. Data from individual production steps are stored in the AutoID / RFID middleware GRAIDWARE. This enables real-time monitoring of production status and complete traceability of all parts.

reference report

With the introduction of the GRAIDWARE® Track and Trace RFID solution at TTI, pallet management has been comprehensively optimized. The solution enables seamless tracking with over 84 RFID reading points. The system improves transparency, optimizes processes and provides live information on stock levels, lead times and more. TTI benefits from more efficient goods management and a significant reduction in workload.

Link: Reference report

AI solutions for optimizing the charging of batteries for E-cars, taking into account a wide range of different input variables and parameters.

Link: Reference report

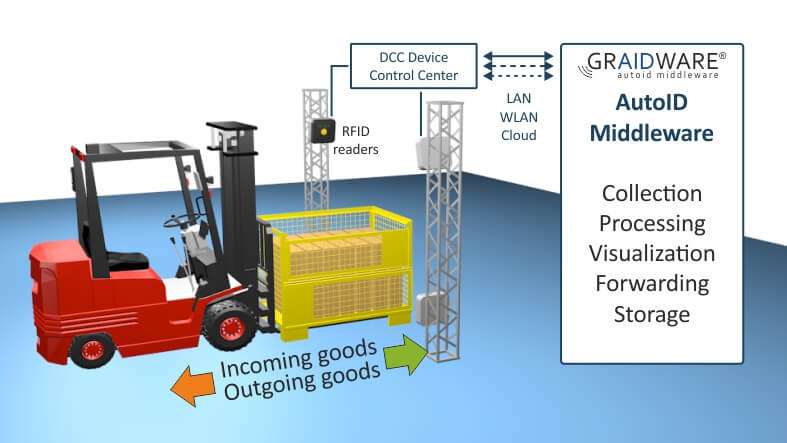

With AutoID / RFID technology and our RFID middleware, goods receipt can be made more effective and digital validation processes can be automated. Pallets of UHF RFID labeled packages of different sizes are read as the forklift passes through the RFID gate and the data is processed, evaluated and transmitted.

Link: Reference Report

✓ Fast bulk detection

✓ Quantity counting of the packages

✓ Error detection through validation

✓ Checking for varietal purity

✓ Correct data transfer

✓ Transparent visualization

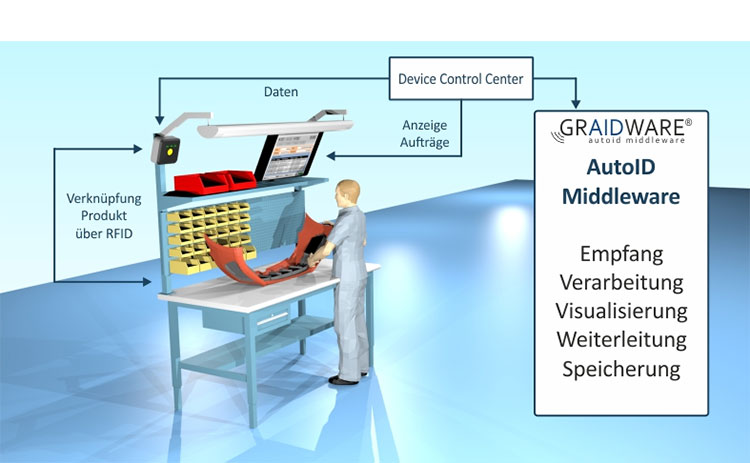

Extensive design drawings and article images are automatically selected from the customer's document management system and displayed and enlarged on screens in the production hall via tablets. All relevant data, from the overview to parts lists and individual item level, is available in digital form, eliminating the need for printing.

Link: Reference report

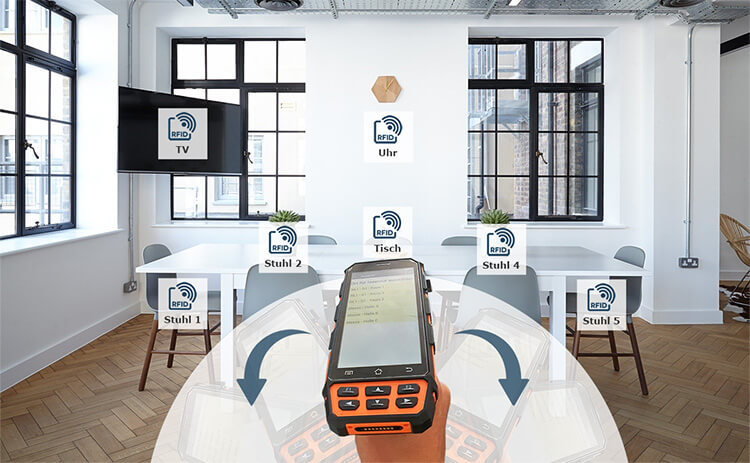

For the inventory of office equipment such as desks, cabinets, office chairs, etc., we use RFID transponders for permanent identification of the inventory to subsequently increase the efficiency of the regular inventories. With a RFID handheld, each room can be documented without the tedious search for inventory markings.

Another application example is the automatic identification of meters, e.g. for electricity, water or gas, which have been marked by the manufacturer using RFID transponders. During the incoming goods inspection, for example, the electricity meters can be automatically assigned to the electronic delivery bills ( EPC ) and compared with the data in the ERP system such as new or old device.

✓ Meter identification & management

✓ Fast sorting of meters

✓ Reconciliation of delivered quantity

✓ Exchange of meter data with ERP

UHF RFID technology enables seed producer KWS to fully automate the identification of its seed sacks by means of an RFID transponder, thus making the European-wide supply chain more transparent. The central data storage via RFID middleware GRAIDWARE forms the basis for comprehensive reporting. reference report

✓ RFID Supply Chain solution

✓ standardized hardware solution

✓ standardized interfaces

✓ standardized data transfer

✓ Use of BI software ( MS Power BI )

The electronic planning board developed by SIGMA is a visualization for upcoming orders in production with the individual setting of time intervals. It shows the production manager the production orders or batches ( paperless production ) planned for selected machines or lines. The production progress is monitored on the basis of the information recorded in BDE / MES. reference report

The RFID solution is used at SOEX's used clothing sorting plant for the identification and transport control of hanging trolleys. The trolleys are identified with RFID transponders and unique ID. At reading points the trolleys can be identified and tracked from each side. The RFID middleware GRAIDWARE takes over the identification and plausibility check of the signals and delivers the result to the trolley control.

reference report

✓ RFID middleware GRAIDWARE

✓ Mapping of all logistics processes

✓ Use of innovative RFID hardware

✓ Optimization of processes

Machines can be connected and controlled with the RFID middleware GRAIDWARE via OPC standard. Machine connection allows for example the automatic loading of machine programs when inserting identifiable products. The correct machine program is selected and executed by an RFID supported identification of the workpiece.

✓ Machine connection via OPC

✓ Control of production processes

✓ Optimization of manufacturing processes

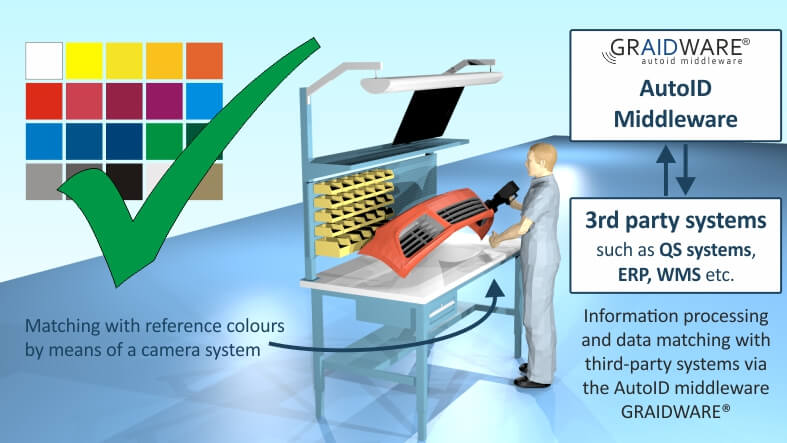

In our automatic colour recognition system, surface colours are recognised by means of a camera system. The camera system can be guided to the product or the product to be inspected can be placed on the camera system. By means of RFID colour recognition a clear component identification is possible.

✓ Automatic colour recognition

✓ Detection of small colour differences

✓ High process reliability

✓ Avoidance of visual inspection errors

✓ Automatic linking of product parameters with AutoID tracking

In cooperation with ZIGPOS we offer a solution for indoor localisation based on RTLS technology within our RFID applications. The applied badges ( e-Paper Displays ) are used to visualise process information, such as container contents, destinations, article information etc. at the marked objects. Their position change leads to bookings in the ERP system ( SAP Business One ).

✓ Order control with RTLS

✓ High transparency in production

✓ automatic WMS bookings

✓ Indoor localization in real time

With our UHF and HF RFID application to control flow of goods on RFID / Auto ID basis, goods or goods carriers can be traced on automatic conveyors, lifts, conveyor belts, etc. Flow of goods is controlled according to configurable rules. For example, goods can be directed to specific positions or machines on a conveyor line.

✓ Control of flow of goods

✓ Increasing degree of automation

✓ Increasing process reliability

✓ Automatic process logging

Your product is electronically registered in the production process by means of RFID tracking ( RFID transponder ), thus ensuring traceability throughout the entire production process. Specific data is carried along through the entire production process and is available at every workstation. Depending on the production step, the electronic supporting file can be extended by process step specific information.

✓ Electronic supporting file

✓ Control of manufacturing processes

✓ Completely digitized image

✓ Quality assurance

✓ Fast reaction to changes

✓ Error prevention through monitoring

✓ no work supporting documents necessary

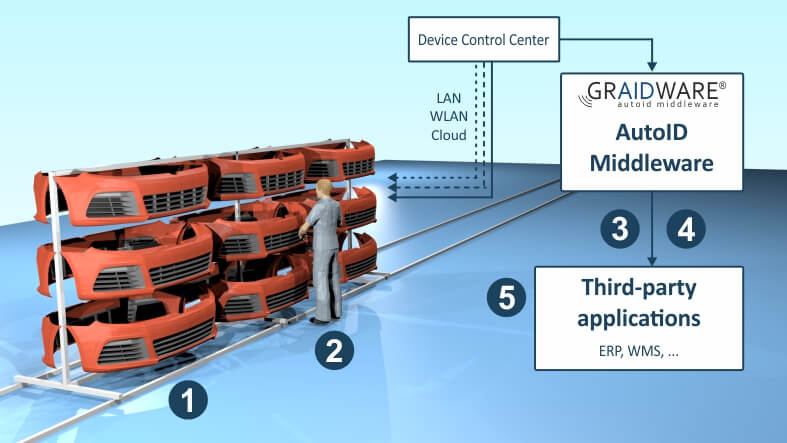

The automated position detection allows the tracking of objects marked with RFID transponders on an automated or manually guided transport rack or a painting skid. Products on a production rack ( skid ) are identified by means of this RFID transponder. The RFID middleware only handles process-relevant data that is exchanged with third-party applications such as ERP systems, plants ( e.g. B+M ), MES.

✓ Automatic position detection

✓ Documentation of quality parameters

✓ Finding deviations & errors

✓ Reduction of process costs

✓ Tracking of painting processes

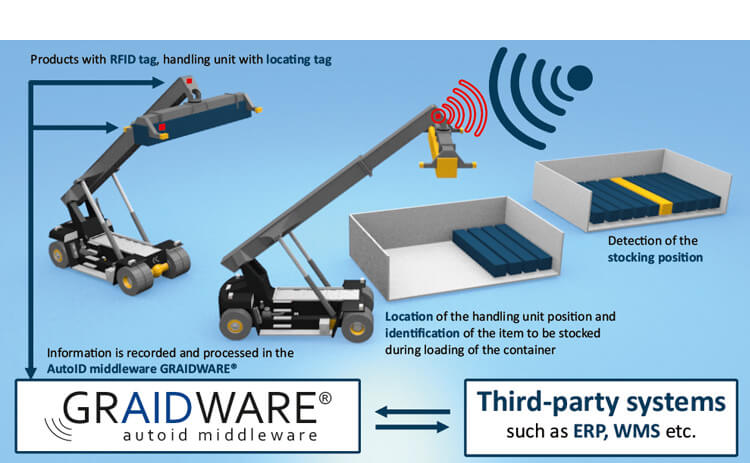

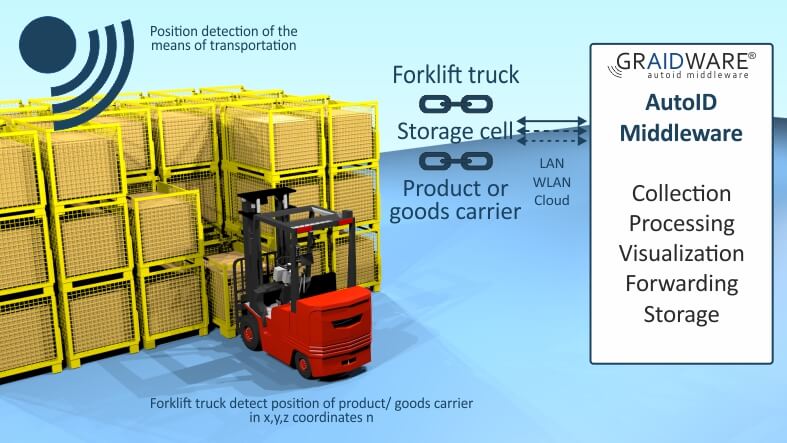

During the introduction of a combined RFID & tracking solution ( RTLS ) at Ortrander Eisenhütte GmbH, forklifts were equipped with modern tracking technology. During storage and retrieval in the block storage, the storage location is tracked via RTLS and linked to the product ( container, pallets ). All data are managed in the RFID middleware GRAIDWARE. Reference report

✓ Tracked storage location detection

✓ fully automatic transparency

✓ high inventory security

✓ fast relocation processes

✓ continuous data flow

✓ Reduction of search times

For suppliers to major automobile manufacturers, the reliable and fast control of goods in and out is becoming increasingly important. With an RFID gate, quantity of goods can be tracked and booked in fractions of a second.

✓ Flow of goods control with RFID gate

✓ Monitoring material flow

✓ Control of process flows

✓ Tracking of the route

With RFID picking, the component is identified at the workstation. This can be done automatically with an RFID reader or also with mobile recording via a scanner (RFID handheld devices, barcode, data matrix or similar). Information and data can be retrieved from third-party business applications (ERP system). Can be combined with a pick-by-light system.

Our RFID application Position Detection in Containers recognizes and monitors the position of Auto ID marked objects by RFID transponders within a load carrier. The identification takes place on a handling unit. When stored in standing containers, the position is determined via RTLS real-time positioning.

✓ Position detection in the container

✓ Avoidance of incorrect deliveries

✓ automatic process logging

✓ Error prevention through automatic monitoring of critical Just in Sequence processes

RFID gates enable automated monitoring of flow of materials and goods within the company and in goods receipt and goods issue. Due to the fully automatic identification, the inventory security is increased. The plausibility check and filtering of the read results at the RFID gate and the data transfer to the ERP system or WMS is carried out by the RFID middleware GRAIDWARE. Reference report

✓ Monitoring of goods

✓ Fast object reading in the door area

✓ Bulk reading of several objects

✓ higher degree of automation

✓ Higher process reliability

✓ Reduction of storage capacity

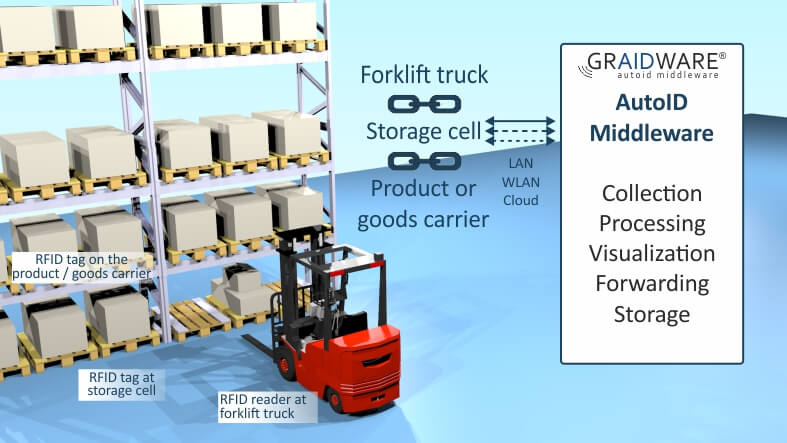

With storage location detection in high-bay warehouses, individual storage locations are automatically detected when approached, for example, by a forklift truck. The objects to be placed into storage are linked to the storage bin. Data is managed with the RFID middleware GRAIDWARE. A prerequisite is RFID tracking of the conveyor vehicles and storage locations.

✓ Storage location detection

✓ Avoiding search times

✓ Use of dynamic warehousing

✓ Avoidance of scanning errors

Through processing of order and shipping data by the RFID middleware GRAIDWARE, loading of goods onto the truck can be monitored by means of RFID gates and RFID forklifts. At the same time, the logistics employee can see the progress and any incorrect loading on a monitor.

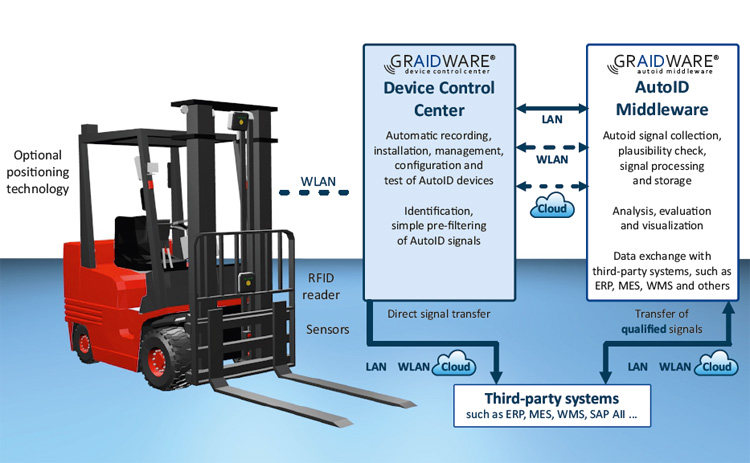

RFID technology can be used to automate identification processes for goods movements by forklift trucks. The RFID hardware is installed on the forklift to identify transported goods or goods carriers. With other technologies, such as positioning solutions / indoor localisation / RTLS, the forklift position can also be used for automatic stock transfer postings.

✓ RFID forklift truck goods movement

✓ Avoidance of missing bookings

✓ higher degree of automation

✓ automatic inventory for subareas

✓ manual booking not required

✓ Avoiding search times

In the RFID middleware GRAIDWARE, storage bins in bulk storage are predefined using item data. If a storage bin is predefined by an external system ( WMS, LVS ), an automatic cross-check is carried out against the recognized storage bin. During stock placement or stock removal, the determined position coordinates are linked to the goods marked with the Auto ID located in the bin during stock placement.

✓ Storage location detection

✓ Increasing degree of automation

✓ Avoiding search times

✓ Avoidance of errors due to manual work steps

In the food industry it is required that containers and / or contents must be cleaned in a certain cycle. Automated RFID tracking of containers enables fully automated cycle monitoring. This ensures reliable compliance with cleaning cycles as well as transparent container tracking and thus inventory security.

Our handheld based position detection allows tracking of RFID or barcodemarked objects on a transport rack with a mobile handheld system. A typical application scenario is the final release of picked components which are delivered just in sequence.

✓ Position detection with handheld

✓ Documentation of quality parameters

✓ Finding deviations and errors

✓ Release of sequence racks

✓ Efficiency enhancement

Just In Sequence ( JIS ) delivery schedules are linked to the goods to be produced or picked. The correct sequence and correct processing are checked and ensured. Machine programs can be loaded automatically. In the event of sequence breaks, operating errors or incorrect allocations etc., this is signalled to the operator.

✓ Just In Sequence Production

✓ Avoidance of wrong deliveries

✓ Avoidance of subsequent deliveries

✓ Process safety

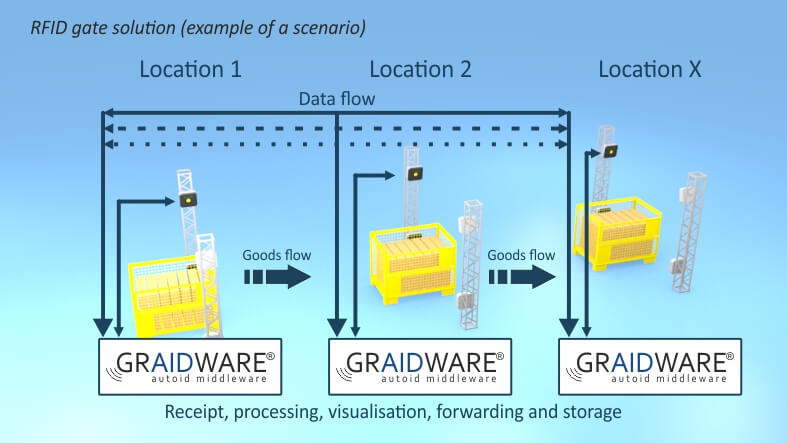

Auto ID data and related information can be exchanged between different RFID middleware GRAIDWARE installations at different locations. Data flow takes place via LAN or WLAN and forms the basis for receiving, processing, visualizing, forwarding and storing Auto ID data.

✓ Direct data exchange

✓ Decentralized data acquisition

✓ central data processing

✓ central data evaluation

✓ Overview of all process-relevant information at all locations

With a cross-plant RFID solution, current location, goods bookings of products and batches can be displayed transparently. This allows complete traceability. When produced parts are delivered to a third-party location for final assembly, they are tracked at the goods receiving gate and posted in the ERP system.

✓ JIS Delivery across plant boundaries

✓ Evaluation of statistics

✓ Evaluation of quality parameters

✓ Traceability Production & Logistics

✓ efficient supply chains

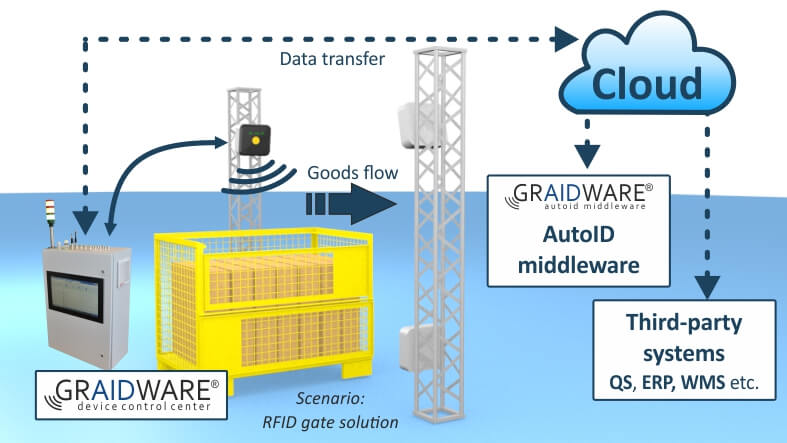

Tracking data and associated information ( e.g. machine data, terminal entries, etc. ) collected at Auto ID stations such as RFID gates can be stored in a cloud memory and retrieved and processed by any third-party application.

✓ Data exchange with cloud services

✓ Monitoring of consignment stocks

✓ Support of delivery management

✓ Data supply of company-owned sites, customers, subcontractors

You still haven't found what you are looking for? If physics allows it and the chemistry is right, we will also realize your project. Please feel free to contact us and share your visions with us.

![[Translate to English:] ROBI [Translate to English:] Carthago ROBI](/fileadmin/Referenzen/AutoID_RFID/carthago_web.webp)

![[Translate to English:] Carthago Reisemobilbau [Translate to English:] Logo Carthago](/fileadmin/Logos/carthago_reisemobilbau_gmbh.gif)