RFID order picking reduce errors

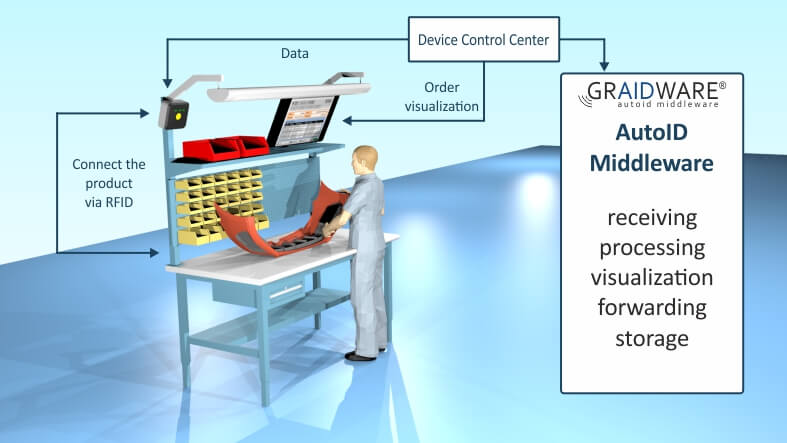

RFID order picking means that the component to be picked is identified at the workstation using RFID tracking. This can be done automatically with an RFID reader or manually with a scanner ( RFID handheld devices, barcode, data matrix or similar ). Alternatively, picking orders can also be selected manually.

All relevant information such as product and parts lists etc. are retrieved and displayed via a terminal at the picking workstation. It is possible to retrieve information and data from third-party business applications e.g. from an ERP system like SAP. After completion the work step is confirmed by the employee.

The RFID order picking reduce errors and can be combined with a Pick by Light system.

Advantages of RFID order picking

- Paperless picking

- Process logging and quality monitoring

- Reduction of errors caused by incorrect picking

Examples of use

- Production

- Intralogistics

- Contract logistics

Functions

- Terminal application for displaying picking lists

- Recording of employee confirmation after completion of picking

- optional: can be combined with a Pick-by-Light system

Components

Software

- Terminal application

System requirements

- Terminal PC

- The RFID Middleware software requirements apply

Licensing

- Part of the RFID middleware GRAIDWARE Basis