Colour detection with RFID

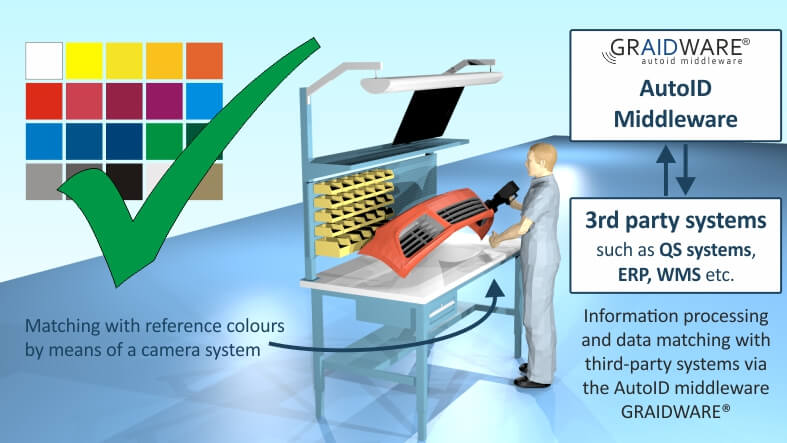

Automatic colour detection is used to identify surface colours by means of a camera system. Either the camera system is guided to the product or the product to be inspected is placed on the camera system. A defined illumination on the camera provides a uniform, reproducible light environment and thus optimum detection results. The detected colour is compared with a reference database and the result is displayed visually or acoustically. If necessary, new colours can easily be taught-in and added to the reference database.

Possible applications are in the quality assurance process or in production. For example, it is possible to check the correct colour match between the parts to be assembled and the basic product. In quality assurance, automatic colour detection can be used for example to detect colour deviations after painting or in the backup process ( for example, if the barcode or RFID transponder is damaged ).

Advantages of automatic colour detection

- Detection of even small colour differences

- high process reliability

- Errors due to a visual inspection by personnel responsible are avoided

- automatic linking of product parameters with Auto ID marking

Examples of use

- Support of the production process

- Quality assurance in the backup process ( e.g. to replace no longer readable RFID transponders in the downstream process )

- Testing the exact colour of add-on parts to the basic component

Functions

- Function for learning new colours

- optional: visualization of the detected colour

- optional: check of the detected with an expected colour ( for example, comparison with stored information from previous painting process )

Components

- embedded computer

- Camera system

- Attachment with light source

System requirements

- Ethernet connection

- Supply 220 V

Licensing

- RFID middleware GRAIDWARE ® Basic site license

- Company base licence colour detection

- Client software per camera system