SIGMA PDA for production and assembly

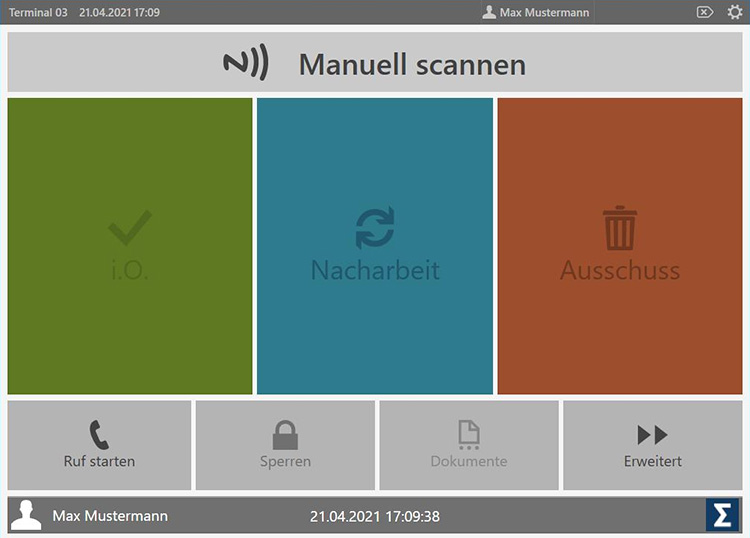

The PDA module is used for production data acquisition and storage of object states of a component over its entire life cycle. After detection of a component by reading the attached RFID transponder or QR code, its status ( ok, nok, locked etc. ) can be booked. Depending on configuration, the booking is forwarded to third party systems.

If required, this software solution can be extended with further modules of the RFID Middleware Graidware product family such as basic fault detection ( BFD ).

The use of SIGMA PDA is part of the strategy paperless production or manufacturing.

The SIGMA PDA terminal module is used for production data acquisition as well as for storing the object states of components over their entire life cycle. It supports the modes goods receipt, assembly and rework, amongst others. After detection of the component its status ( ok, nok, locked etc. ) can be booked.

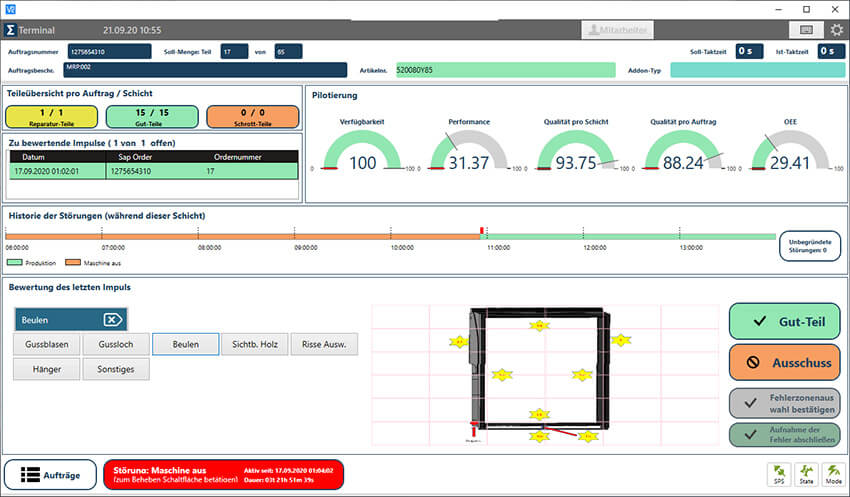

Customer-specific evaluations

- The basis is data collected and stored in the process

- Creation of individual key figures dashboards

- Visualization of the key figures at the terminal

- Visualization / presentation of key figures on Android devices

Overall Equipment Effectiveness ( OEE )

The OEE, or overall equipment effectiveness, is a created key figure that reflects the measure of the added value of a plant and is defined by the factors availability, performance and quality.

The GRAIDWARE OEE component includes the

- manual recording of downtimes, such as a break or planned maintenance

- Automatic transfer of error messages from the plant's PLC and their allocation to a defined error structure.

- Integration of quality recording per produced part

- Assignment of the machine to shift models

- Evaluation of the measured cycle time in relation to the preset cycle time

- Display of the defined KPIs on the machine

The GRAIDWARE OEE is a component of the GRAIDWARE Paperless Manufacturing product family. The use of RFID technology guarantees the highest degree of automation in data determination and data assignment to the produced part.