Direct data exchange

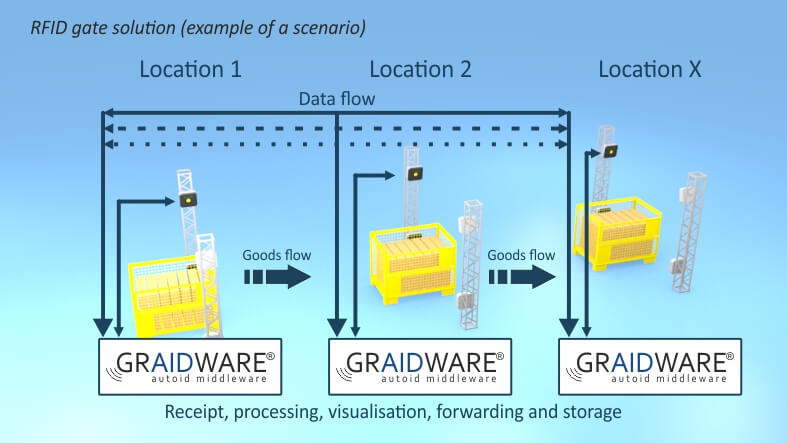

Auto ID data and related information can be exchanged between different RFID middleware GRAIDWARE ® installations at different locations. Thus, production and logistics processes between suppliers or parts of the company ( for example, when supplying module centers ) can be simplified and optimized. A supply chain as part of the supply chain management is realized across plant or company boundaries.

For the flow of materials, a correspondingly appropriate flow of information and data is thus guaranteed. For example, goods that were created and sent at location 1 can be directly assigned to a data record after identification at the goods-in area of location 2.

Advantages of direct data exchange

- Sites that work with common AutoID objects ( goods, articles, goods carriers, load carriers, etc. ) have the same database around the object

- Data for an AutoID object does not have to be time-consuming created / managed at the target location

- Comfortable data provision

- High degree of process automation

Examples of use

- Support of supply chain / logistics chain, supply chain management

- Delivery to company-owned sites, customers or subcontractors

Functions

- Transfer of AutoID data, such as RFID identification numbers ( e.g. UID or EPC ) and related information between different GRAIDWARE ® installations at different sites

- Configuration of a trigger process, e.g. for production completion or dispatch gate machine control

Components

Software

- RFID Middleware GRAIDWARE ® Additional component communication module, at source and target data site