Processes in plastics production

With help of RFID technology, processes - in this case, for example, in the manufacturing of painted plastic parts - can be made consistent and transparent, starting with production, through logistics, to shipping.

AutoID / RFID middleware as process basis

Within AutoID-based processes, work equipment, production steps and Auto ID data can be identified, monitored, controlled and configured with help of the rfid middleware GRAIDWARE ®. In addition, the middleware forwards data to higher-level business applications, such as ERP, QA or WMS systems. Learn more about the RFID middleware here.

Orders are selected and quality inspection results are recorded. If the product is OK, a unique RFID tag is created, which allows the product to be tracked in the production process. If desired, the RFID transponder can continue to be used for the warranty process after the product is delivered.

Parts required in production processes that are too small to attach an RFID tag are filled into a container. This container is then given its own RFID label. At the same time, the quantity of items produced is reported back to the ERP system. This means that the labelled container can be clearly identified in subsequent processes.

Purchased parts that have not yet been tagged with an RFID tag by the supplier can still be subsequently identified. In this way, it is also possible to identify and track purchased parts in the overall process.

The position of products on the load carrier is detected automatically. A comparison of the painting equipment with the painting plan takes place. This data is used for later evaluations for quality assurance.

The attached RFID tag is used to identify products within an automated process. Quality inspection results are documented. If the product is OK, it is released for further processing or marked for rework.

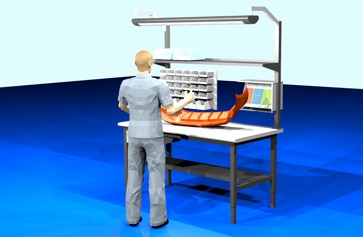

Before picking, for example when selecting from an intermediate storage, the product is identified at a control workstation by means of the RFID tag. The connection with the call-off order is made and the results of the quality inspection are recorded. If the product is OK, it is released for further processing.

The planning board developed by SIGMA visualizes the production orders and production lots which are running on certain machines or lines or which are pending for them. The production progress is monitored on the basis of the information recorded in the PDA.

Learn more…

At control workstations, the product is automatically recorded and clearly identified by means of the RFID tag. All processing steps are displayed. The machine program is loaded automatically via machine interface. After processing, quality control is carried out and the product is released for further processing.

At the end of picking, the product is automatically recorded at a control workstation and uniquely identified by means of the RFID tag. All processing steps that have taken place are displayed. The final inspection and recording of the results as well as the final release for delivery take place.

At goods-out, products are automatically recorded and booked in a goods carrier or in precise JIS sequencing. Incorrect deliveries are avoided. The data can be transferred to a third party system ( ERP, WMS etc. ) and, if required, can be made available to the customer or other plants via a cloud storage or a secure direct connection for goods-in control and booking.