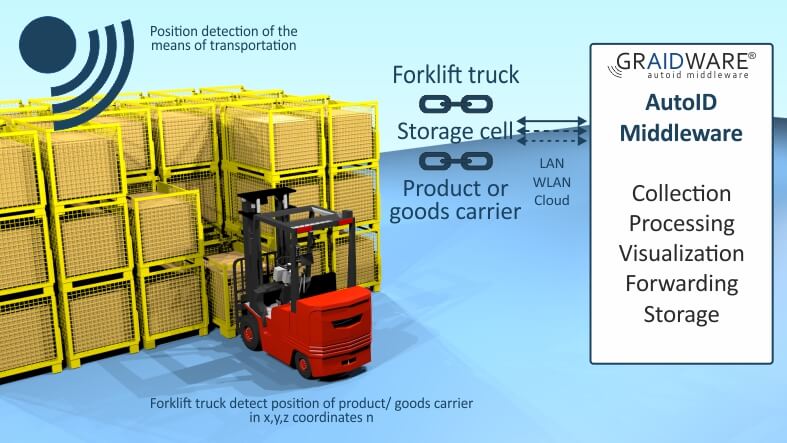

RTLS storage location detection in bulk storage

With the automatic recognition of storage zones by means of a real-time locating system ( RTLS ), the position is detected with an accuracy of up to 0.5 m. The storage areas to be monitored can be freely defined. Optionally, the detection of the fork height of a forklift truck in use is possible by means of the locating system. In Auto ID / RFID middleware GRAIDWARE ®, storage locations are predefined with the help of position data. If a storage location is predefined by an external Warehouse Management System ( WMS ), an automatic cross-check is carried out against the recognized storage location. Alternatively, a recognized storage bin can be passed on to an external system without a plausibility check.

In the storage or retrieval process, the identified position coordinates are linked to the AutoID marked goods or goods carriers ( e.g. articles, packages, skeleton containers, pallets, containers, etc. ) during storage. Posting information is transferred to connected third-party systems ( for example, SAP, WMS ). The vehicle drivers can be provided with transport orders for the forklift truck etc. as support or for process control. Optionally, recognized objects, identified storage bins or storageareas can be visualized.